- Home

- Company

- Products

-

Solutions by Industry

- Stock / Used

- Customer Care

- Quality

- News

- Contact

- info@houtris.com

- +357.24811216

We build tailored, efficient solutions to help keep your jobs – big and small – on time and on budget.

The extensive range of granulators produces high-quality regrind from a wide assortment of plastic waste resulting from various processes. Rapid solves the problems associated with plastic recycling by matching the right technology with specific applications

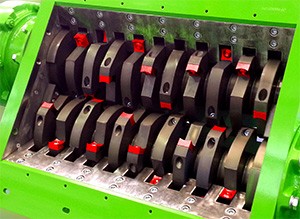

Shredders driven by two / three or four electric or hydraulic motors suitable to be used in different fields.

Solutions with selection screen that allows to obtain a controlled shred-size of the output material on three dimensions.

Different shredding chamber dimensions, blade types and thickness and selection screens allow each machine to be tailored to individual customer requirements

S. Houtris Ltd does not only make amazing big and medium cranes, but successfully covers the light segment too: cranes in this range can lift from 2 to 10 txm and combine power, agility and effectiveness.

S. Houtris Ltd medium duty cranes in the medium range have a lifting capacity between 10 and 30 txm, and countless and versatile configurations.

S. Houtris Ltd heavy duty cranes have a lifting capacity between 30 and 300 txm and are ideal for working with heavy loads in a safe and effective way even under extreme situations.

S. Houtris Ltd special cranes demonstrate their universal applicability even in the most difficult material transport jobs. They can be use as magnet cranes, power plant cranes, loading cranes, special cranes on large open-pit mining equipment or as robotic cranes.

FreeAccess stands for freedom. Light vehicle classes place high demands on the tail lift: it should be light, so that additional payload is available, and at the same time flexible, because it is not needed at any time. The FreeAccess product group precisely fulfills these criteria.

Open, closed, up, down – these options can be used to define the requirements on a tail lift. After all, not every user intends to load five fully packed trolleys at the same time.

High loads on high platforms, different drivers in multi-shift operation, varying framework conditions at the unloading sites, long service life, diverse carrier vehicle types and, not least: The tail lift as a business card for the customer.

The manually unfolding BC 1000 F2 is a favorite solution for trolley transport with frequent loading and unloading at ramps. When at the ramp, this tail lift disappears out of sight under the vehicle. When needed, however, it is quickly available for use.